The Role of CAD and 3D Designs in Manufacturing Jewelry

You may be wondering as to ‘what is CAD?’ ‘How does it work?’, this guide will take you through the whole process so you get a good idea of what to expect from your CAD design.

What is CAD?

CAD means ‘Computer Aided Design’. In 3D CAD jewelry design, CAD refers to using specialized 2D and 3D modeling software to create casts.

Designers use CAD tools to create ‘STL files’ (a type of file format) of prototype casts, which a milling or 3D printer can then manufacture.

Why Do You Need 3D For Modern Jewelry Design?

The method of hand-carving wax blocks to make jewelry designs to get the appropriate shape is a tedious task that requires great skill and time.

That all came to an end with CAD designs. Designers can accomplish amazing things with CAD, like mirroring components, copying and pasting elements, and guaranteeing precise symmetry.

How Does CAD & 3D Designs Help in Jewelry Making?

CAD and 3D jewelry design makes the process easy for jewelers, it lowers the possibility of mistakes and eliminates the need for pricey wax molds.

Companies/brands produce the exact desired designs and provide customized services to clients.

This process saves time, even though intricate designs could involve assembling multiple 3D-printed elements. Let us take you through the process.

Step-1: Idea Generation- Rough Sketches and Conceptual Design

Customers interact with a design expert to discuss their ideas and needs. The design consultant then sketches possible designs. The buyer reviews a rough conceptual 3D rendering of the ring created by the CAD designer from these sketches.

Step 2: CAD Design on Computer

The design process begins with a four-view specification sheet to visualize the ring’s dimensions and design from all perspectives and angles.

Along with which CAD and 3D design is made which helps to estimate the diamond size and metal weight. This deep dive clarifies how every facet of the ring will look.

A CAD designer develops a 3D ring rendering using design consultant sketches and briefs. This render is given in STL Files. Later they make the CAD and 3D designs are shared for design approval to the client. To run the STL file you will need an independent software which users may not have. This collaboration guarantees the ring design meets all requirements.

Step 3: 3D Images

At this point, the manufacturer receives the CAD engagement ring file. Customers occasionally ask to receive a soft copy.

The buyer has a look at this model so they may verify the scale, size and accuracy of the design. The buyer is also supposed to review the bandwidth, ring size, prong style and height.

After looking at this 3D model if a customer has any requests for change they can let the designer know and it will be done. The changed design will be shared again with the user for confirmation.

Step 4: Client Approval for Human Touch

Client approval is essential to give a personal touch to theCAD design process.

Only once a design is confirmed by the client, will it go into production.

Couples can view the online images and review it, once it is approved then the design will go into production.

Looking atCAD jewelry design has several advantages. It makes exact imagination and modifications possible, which in turn, enhances the performance of designers.

Another benefit is that it saves money because it doesn’t require expensive molds and minimizes material waste.

Additionally, the procedure speeds up the transfer from design to production, saving time.

It also makes it possible to create distinctive, personalized rings that precisely capture the couple’s vision.

Customers can see a reflection of the CAD engagement ring design they want thanks to 3D designs and CAD which makes it an essential tool in the expanding online ring shopping trend.

This technology guarantees individualized, effective, and high-quality results.

What Should a Customer Look For In a CAD Design?

Many people have this question on their mind when they go ahead with a CAD design. Let us break it down for you:

- Bandwidth- Is the thickness of the ring satisfactory? Do you want to make it more slim or want to make it wider? These are a few questions you should ask yourself.

- Height- Is the height of the ring suitable? Does the stone look awkward? A ring with good height will have a good appeal. So, it is recommended you go for a subtle ring.

- Ring Size– Is the ring the same size you ordered? If you feel that the size can be reduced or increased do let your designer/team know and they will make the adjustments.

- Metal Color (If Gold)– Is it the same metal color you ordered? If not then you can have it changed by contacting the team.

- Engraving- You can mention the font style for your engraving is it cursive or normal font or any special text/number/design to be engraved on the ring. This however will only be seen on the final ring and not on the CAD/3D design.

What are The Benefits of Previewing a 3D Ring Design?

There are various benefits to creating engagement rings with CAD and 3D printing. It saves couples from having to spend hours looking through rings in stores.

Alternatively, they might collaborate to create a personalized ring that perfectly captures their tastes.

You can get an idea of the total diamonds including the size and weight along with the gold weight that is required to craft your dream ring.

You will get to see the size in real-time and upfront. So, if you wish to make any changes then you can have them made before the design hits production.

Family members who can offer feedback remotely can also be involved in this process. In addition, the total expense is much less than with conventional techniques.

What is The Difference Between CAD and Finished Product?

Straight Prongs Issue

The finishing touches are where the final jewelry piece differs most from the CAD design.

Extra metal is included in CAD engagement ring files for polishing and finishing, giving prongs a much taller appearance and sharper edges than what would be in the final product.

Although it can be misleading in renders, the bulkiness of the design is to maintain structural integrity during casting.

It is essential to inform buyers about this process since the finished product will have polished prongs for brightness and bent prongs to secure the stone. And it will look much different than the CAD render design.

Basically CAD is only for production purposes, the original bulky design is transformed into an elegant, gorgeous ring with skillful finishing and proper casting.

Have a look at the image below for clarity.

Bezel Look Larger & Smaller

The way bezel settings look in CAD engagement ring design versus the finished product is a bit different and that is normal. As, bezels may appear bigger or smaller in CAD renders than when polished.

The excess metal seen in CAD renders—is required for casting and refining the piece—this is the reason they both will look different.

But after the ring is polished, the bezel setting will be adjusted to its proper size, giving the illusion of something streamlined and balanced.

Have a look at the image below for clarity.

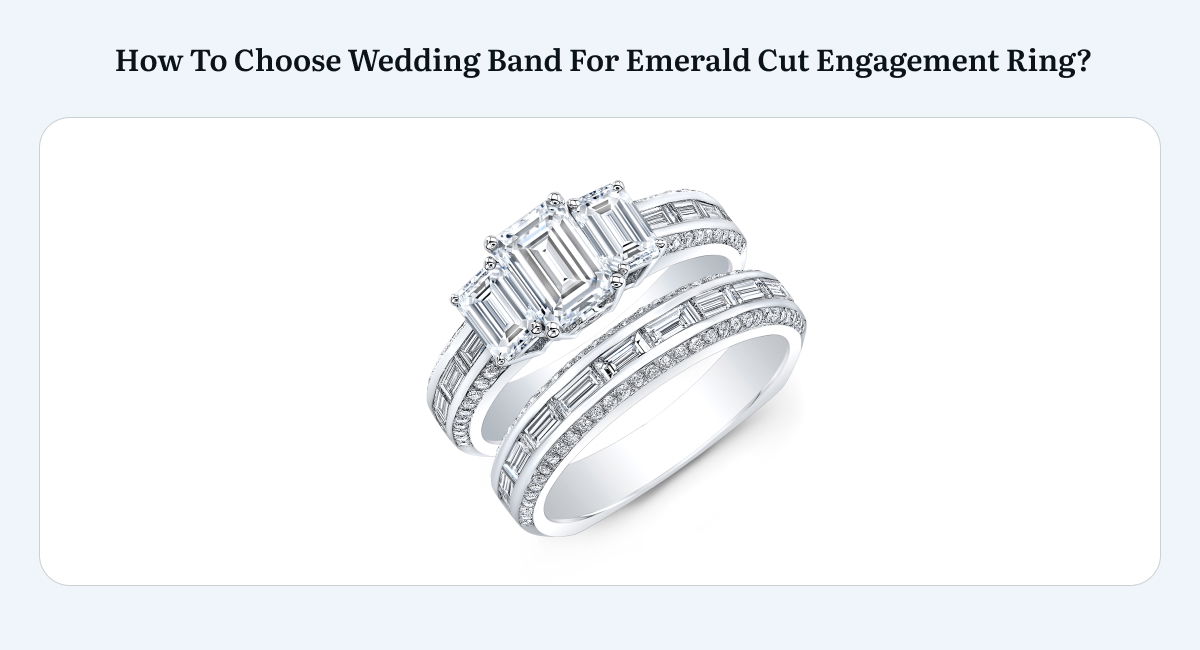

Wedding Band & Ring Flush

The flush setting differs between CAD design and wedding band. CAD representations may show a gap between the band and the flush setting, thus making the size look confusing.

But that is not the case, this gap is essential for casting and finishing but may worry buyers who want a flawless fit. No need to worry the final product will fit perfectly.

Have a look at the image below for clarity.

Conclusion

We at Loose Grown Diamonds, guarantee that you will get the ring you have wished for. These CAD designs are only to benefit both of us, in understanding what you truly want. These design may look bulky, weird, a bit tall and what not. But that is just because we have made it that way, so when casting the design there is space for change/polishing/designing.

FAQs

What is The Difference Between 3D and CAD?

The method of making digital representations of items is known as CAD (Computer-Aided Design), and the term “3D” describes how these models are three-dimensional. While 3D refers to the visual representation of these ideas in a three-dimensional environment, CAD refers to the software tools used to create objects, including jewelry.

Can I Make Changes to The CAD Design?

Indeed, you can make changes to CAD designs at any point during the design process. Thanks to this versatility, clients can improve their designs to make sure it fits their needs.

How Does CAD Help in The World of Jewelry?

Jewelry designers may now build exact and detailed digital models of jewelry thanks to computer-aided design (CAD). This process helps in improving customization choices, and fostering communication between designers and clients.

How Long Does The CAD 3D Jewelry Design Process Typically Take For an Engagement Ring?

The design’s complexity and the designer’s workload are two variables that can affect how long the CAD for an engagement ring process takes. However, creating and perfecting a CAD for an engagement ring usually takes a few days to several weeks.

Why are CAD Files Important For Jewelry Design?

CAD files for engagement rings are digital blueprints for jewelry creations, as they offer all the details about each item’s specific dimensions, forms, and characteristics. These files help ensure precise design reproduction and streamline production by easing communication between designers, manufacturers, and clients.

Can There Be Color Differences Between CAD Designs & The Finished Product?

Variations in materials, lighting, and manufacturing methods can lead to color differences between CAD plans and the final product. Clients must be aware of this potential and communicate any color preferences or worries to their jeweler or designer.